Automatic control and mill-proven benefits for quality and profit

Specialized material makers report reasonable increases with USTER® EVS texture examination frameworks

Specialized materials is the most quality-touchy segment of the whole business, and numerous items for specific and execution end-utilizes are at the largest amount of this prerequisite. For extreme control and security of value, texture makers need a top innovation arrangement which removes the mystery from delivering the quality their clients need. That is the place the USTER® EVS robotized texture assessment frameworks offer huge advantages, demonstrated in various establishments around the world – and displayed at up and coming Techtextil.

Computerized visual texture examination is a fundamental resource in advancing quality for a wide scope of specialized materials and execution clothing. Applications in design, car, development, risk assurance, prescription, flying and aviation have the absolute most stringent quality criteria. Yet, textures for goods, sports and utilitarian apparel should likewise fulfill the ideal guidelines that significant brands need to maintain their notoriety and fulfill client desires.

All texture makers intend to convey the quality their clients determine, while likewise limiting piece and seconds to ensure their own effectiveness and productivity. The diverse texture creation and completing procedures contain a lot of chances for texture deficiencies to emerge. USTER's robotized texture assessment framework bring quality leveled out, paying little heed to the complexities of the assembling stages. Error prone human judgment and fluctuating dimensions of employable capacity and experience are never again basic to the generation of predictable, solid quality. Precise programmed quality control turns into a necessary piece of assembling.

Beginning time control with USTER® EVS Q-BAR disposes of the requirement for manual assessment after creation. USTER® EVS FABRIQ VISION guarantees dependable observing, utilizing computerized control during middle of the road and last examination. The framework's capacity to catch any unmistakable deficiencies – with a demonstrated and reliably high rate of imperfection identification – and its improved texture reviewing shield the maker from the danger of harming claims

Colored textures present the specific additional test of shading consistency. USTER® EVS FABRIQ SHADE has the arrangement, observing in-line shade variety in basically any procedure where shading is basic, without the need to cut texture swatches for lab tests.

Streamlining benefit

Programmed texture review is the best approach to accomplish ideal quality, to lessen less than impressive and scrap textures and to amplify texture yield. The cut improvement programming module of USTER® EVS FABRIQ VISION and USTER® EVS FABRIQ SHADE upgrades texture yield per class, as indicated by the settings. The framework works by denoting any imperfections in the texture during assessment. The situation of each imperfection is synchronized with Optimized Cut Control (OCC), which stops the cutting table at exactly the opportune spot, ensuring mistake free cutting. OCC can likewise recognize and feature surrenders which require administrator activity, making the procedure progressively productive.

Just a single administrator is expected to supervise the whole generation, investigating abandons and dismissing or tolerating them. The framework is self-getting the hang of, decreasing superfluous alerts after some time. The administrator sends the texture move, with its deformity report, to the cutting station, where issues can be checked, retouched or expelled as required. This spares time, as the administrator has just to oversee move preparing, as opposed to really investigating the texture.

Demonstrated outcomes

USTER® EVS programmed texture assessment innovation is established on over 25 years of spearheading advancement in the field. Today, in excess of 1,000 establishments in wide-extending material portions overall recognize it as the way to cost investment funds and improved market aggressiveness.

USTER® EVS clients as of now investigate more than 60 million meters of texture for every day. Numerous organizations which introduced EVS lines in the mid-Nineties have as of late updated their programmed texture assessment frameworks with USTER® EVS FABRIQ VISION and USTER® EVS FABRIQ SHADE.

A few clients have given important criticism on real advantages of the frameworks. A German texture finisher reports that in the initial a half year after establishment of USTER® EVS FABRIQ VISION, it had the option to deliver 1.2 million meters of texture without a solitary client guarantee. Another firm, an European chief in defensive apparel, bought two frameworks of USTER® EVS FABRIQ VISION and USTER® EVS FABRIQ SHADE in 2017. Just as lessening claims, the organization likewise figured out how to diminish work costs by sparing 14 administrators.

An Italian client introduced USTER® EVS FABRIQ VISION and USTER® EVS FABRIQ SHADE close by programmed cutting and bundling machines, supplanting manual investigation. Inside three years, off-quality and scrap diminished by over 3%.

For more subtleties and to talk about individual necessities, invested individuals are prescribed to meet the specialists at Techtextil. Texture makers and finishers are free to give corner staff any difficulties with respect to programmed texture assessment at the approaching occasion, in Frankfurt, Germany, from May 14 to 17. The USTER® EVS Q-BAR, just as different individuals from the USTER® EVS texture examination family, will be introduced. Visit USTER at corner D05 in Hall 3.0, together with German operator Elmatex.

Specialized materials is the most quality-touchy segment of the whole business, and numerous items for specific and execution end-utilizes are at the largest amount of this prerequisite. For extreme control and security of value, texture makers need a top innovation arrangement which removes the mystery from delivering the quality their clients need. That is the place the USTER® EVS robotized texture assessment frameworks offer huge advantages, demonstrated in various establishments around the world – and displayed at up and coming Techtextil.

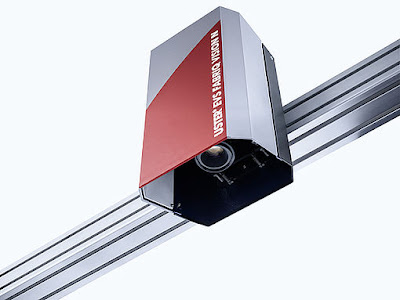

USTER® EVS FABRIQ VISION – The fabric quality assurance system

Computerized visual texture examination is a fundamental resource in advancing quality for a wide scope of specialized materials and execution clothing. Applications in design, car, development, risk assurance, prescription, flying and aviation have the absolute most stringent quality criteria. Yet, textures for goods, sports and utilitarian apparel should likewise fulfill the ideal guidelines that significant brands need to maintain their notoriety and fulfill client desires.

All texture makers intend to convey the quality their clients determine, while likewise limiting piece and seconds to ensure their own effectiveness and productivity. The diverse texture creation and completing procedures contain a lot of chances for texture deficiencies to emerge. USTER's robotized texture assessment framework bring quality leveled out, paying little heed to the complexities of the assembling stages. Error prone human judgment and fluctuating dimensions of employable capacity and experience are never again basic to the generation of predictable, solid quality. Precise programmed quality control turns into a necessary piece of assembling.

Beginning time control with USTER® EVS Q-BAR disposes of the requirement for manual assessment after creation. USTER® EVS FABRIQ VISION guarantees dependable observing, utilizing computerized control during middle of the road and last examination. The framework's capacity to catch any unmistakable deficiencies – with a demonstrated and reliably high rate of imperfection identification – and its improved texture reviewing shield the maker from the danger of harming claims

Colored textures present the specific additional test of shading consistency. USTER® EVS FABRIQ SHADE has the arrangement, observing in-line shade variety in basically any procedure where shading is basic, without the need to cut texture swatches for lab tests.

Streamlining benefit

Programmed texture review is the best approach to accomplish ideal quality, to lessen less than impressive and scrap textures and to amplify texture yield. The cut improvement programming module of USTER® EVS FABRIQ VISION and USTER® EVS FABRIQ SHADE upgrades texture yield per class, as indicated by the settings. The framework works by denoting any imperfections in the texture during assessment. The situation of each imperfection is synchronized with Optimized Cut Control (OCC), which stops the cutting table at exactly the opportune spot, ensuring mistake free cutting. OCC can likewise recognize and feature surrenders which require administrator activity, making the procedure progressively productive.

Just a single administrator is expected to supervise the whole generation, investigating abandons and dismissing or tolerating them. The framework is self-getting the hang of, decreasing superfluous alerts after some time. The administrator sends the texture move, with its deformity report, to the cutting station, where issues can be checked, retouched or expelled as required. This spares time, as the administrator has just to oversee move preparing, as opposed to really investigating the texture.

Demonstrated outcomes

USTER® EVS programmed texture assessment innovation is established on over 25 years of spearheading advancement in the field. Today, in excess of 1,000 establishments in wide-extending material portions overall recognize it as the way to cost investment funds and improved market aggressiveness.

Spectroscope of USTER® EVS FABRIQ VISION

A few clients have given important criticism on real advantages of the frameworks. A German texture finisher reports that in the initial a half year after establishment of USTER® EVS FABRIQ VISION, it had the option to deliver 1.2 million meters of texture without a solitary client guarantee. Another firm, an European chief in defensive apparel, bought two frameworks of USTER® EVS FABRIQ VISION and USTER® EVS FABRIQ SHADE in 2017. Just as lessening claims, the organization likewise figured out how to diminish work costs by sparing 14 administrators.

An Italian client introduced USTER® EVS FABRIQ VISION and USTER® EVS FABRIQ SHADE close by programmed cutting and bundling machines, supplanting manual investigation. Inside three years, off-quality and scrap diminished by over 3%.

For more subtleties and to talk about individual necessities, invested individuals are prescribed to meet the specialists at Techtextil. Texture makers and finishers are free to give corner staff any difficulties with respect to programmed texture assessment at the approaching occasion, in Frankfurt, Germany, from May 14 to 17. The USTER® EVS Q-BAR, just as different individuals from the USTER® EVS texture examination family, will be introduced. Visit USTER at corner D05 in Hall 3.0, together with German operator Elmatex.

কোন মন্তব্য নেই